Indonatura, a Netherlands based company and brand owner of Naturalissmi,

reached out to Clarion to develop unique Ayurvedic Specialised products to add

to their range. Clarion tied up with the reputed 150 year old ayurvedic research

lab, Sankunni’s to identify potential diseases that could be addressed through

ayurvedic cosmetic applications. Ayurvedic solutions were identified for psoriasis,

anti-ageing, anti-blemish, skin glow and skin toning and products developed based on

this finding.

Work was initiated in cosmetic chemistry to design a base that can hold ayurvedic

raw material without them losing their ayurvedic goodness. The products were developed

and clinically tested for efficacy. Care was taken to ensure they also appealed through

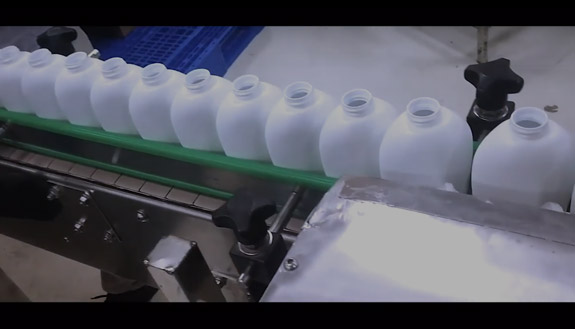

texture and sensory qualities such as fragrance and looks. Working with suppliers, packaging

formats were developed. Artwork for packaging was created in compliance with all European

regulatory requirements.

Over the course of the next year documentations were exchanged, consumer testing samples

were created, toxicological assessments were conducted and we were ready for launch. Before

the launch real-time stability data was shared with the brand owners. Indonatura was happy

with the work and signed up with Clarion. Soon the two products, Psoracare and Anti-ageing

creams were manufactured and shipped.

The product is now available in stores in Europe.

Products developed were tested for efficacy and checked for appeal of texture, fragrance and looks, before shipping.